First, an overview of

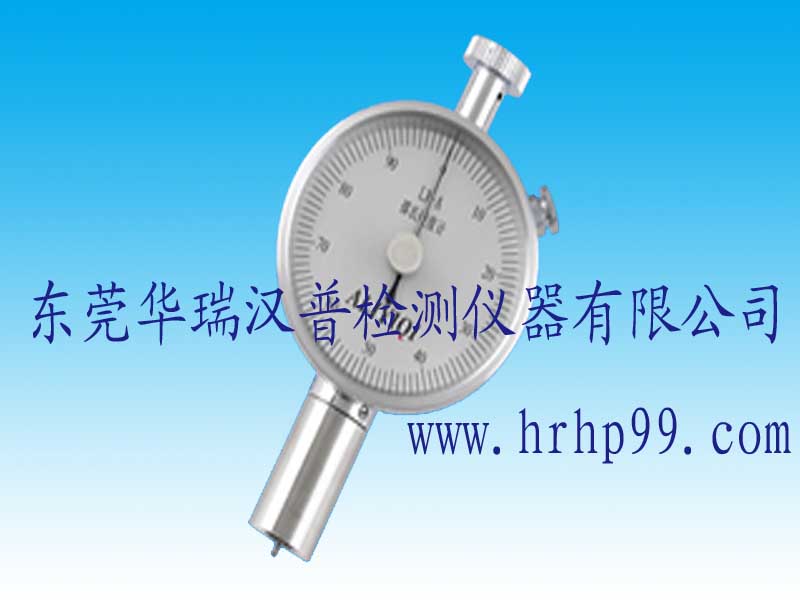

Rubber • Rubber • Plastics Plastics hardness is a reflection of overall performance, while the Shore hardness is a measure of

Rubber • Plastic hardness of a more sophisticated measurement tools. The product uses "ISO 868

-1986 Plastics and ebonite - Determination of pressure with Shore hardness tester hardness "•" ISO 7619 Rubber

Rubber with a Shore hardness determination of indentation hardness "international standards to organize production and testing. Products

According to application requirements are divided into desktop and portable hardness tester hardness tester two types.

Second, the structure forms • Category

Press hardness tester pressure needle shape can be divided into A-• D-type and O-three kinds.

Hardness model • parameter table (mm)

Measuring their ability to model the overall shape of the pressure measuring head length dial needle scale

A 8.1N 1Kg cone voltage pin top angle of 35 ° 2.5 0-100

D 44.5N 5Kg end of the sharp 30 ° 2.5 0-100

O 8.1N 1Kg spherical radius of 2.38 2.5 0-100

Third, the use of instructions

Test sample thickness is greater than 6mm, not enough thickness to the same material base set, but not more than

3-layer. Test area can not be less than the pressure foot (ф18mm) edge.

1. Desktop hardness measurements: first hardness pull up, then put into the specimen, and then hardness tester

Slowly down to measure the average of the three pilot sample hardness value.

2. Portable hardness tester measurements: hardness by hand grasp, so that sufficient pressure equilibrium with the sample pressed (so

Pressure in the table below), a second reading the instructions, when the table in order to measure the average of three points

The hardness of the specimen.

Note: Routine use of choice of A-type or D type, when the A-hardness value is greater than 90 ° when you recommend the use of D-type or

Select other models. After use should be properly kept.

|